|

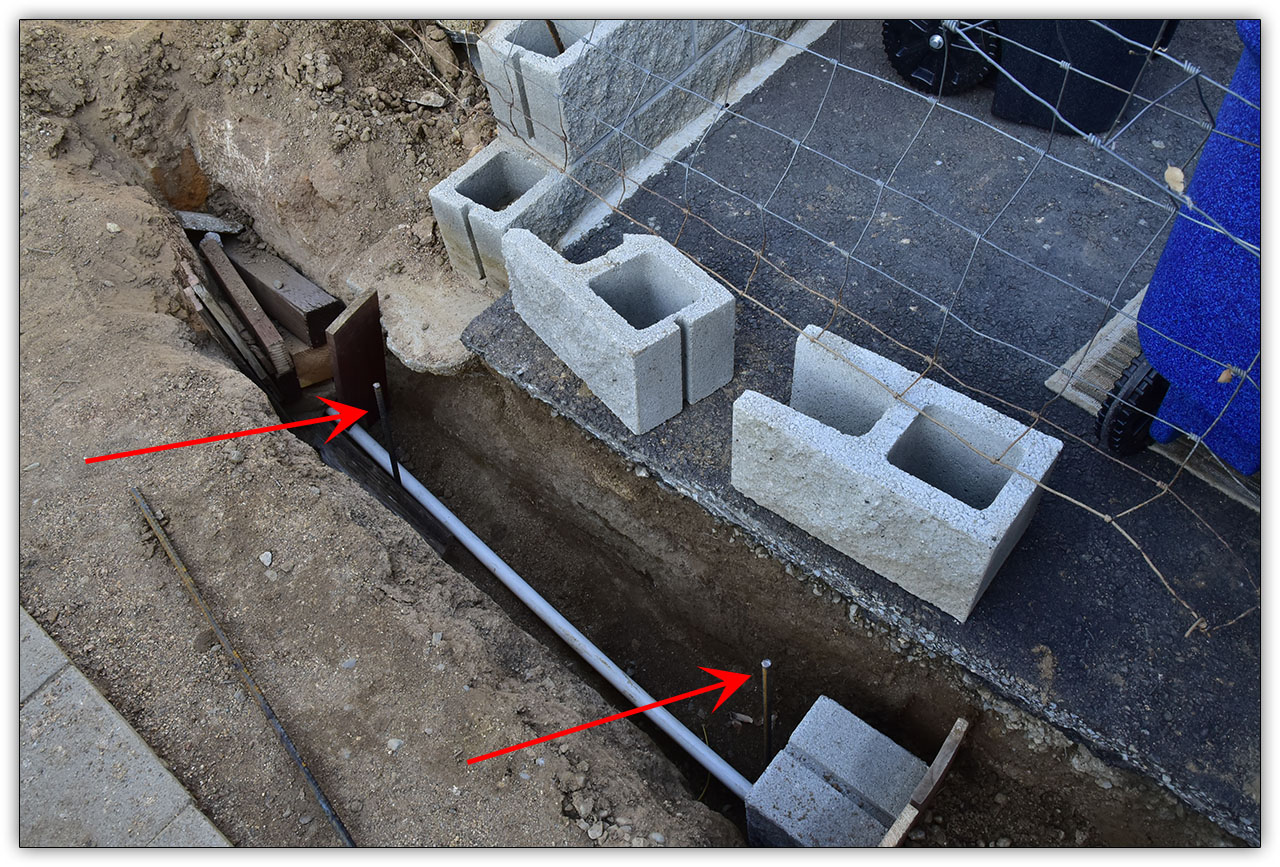

Retaining Wall and Gate

About the Photo Sequence

With the intent to complete the retaining wall, I got back to work on it. Procrastination is a fancy word for lazy so I got off my dead ass and got to work. I added a few rows of bricks and added a larger gate. Why a larger gate? To get the riding mower through it so I don't have to drive it all the way around the house. This documents the build.

|

Photo Details

This photo sequence contains 20 frames. Each frame is a finite 1280 pixels wide but height was left to its own based on the crop. I based the picture size on an email program's display window asuming that the picture would not be automatically resized to fit. This technique kept the file size down, the largest being just less than 545k making it easy to send and receive through email. All photos were taken with a Nikon D810.

Download Photo Project

|

|---|