|

Heat Distribution System

Step 2 Fan Preparation About the Photo Sequence

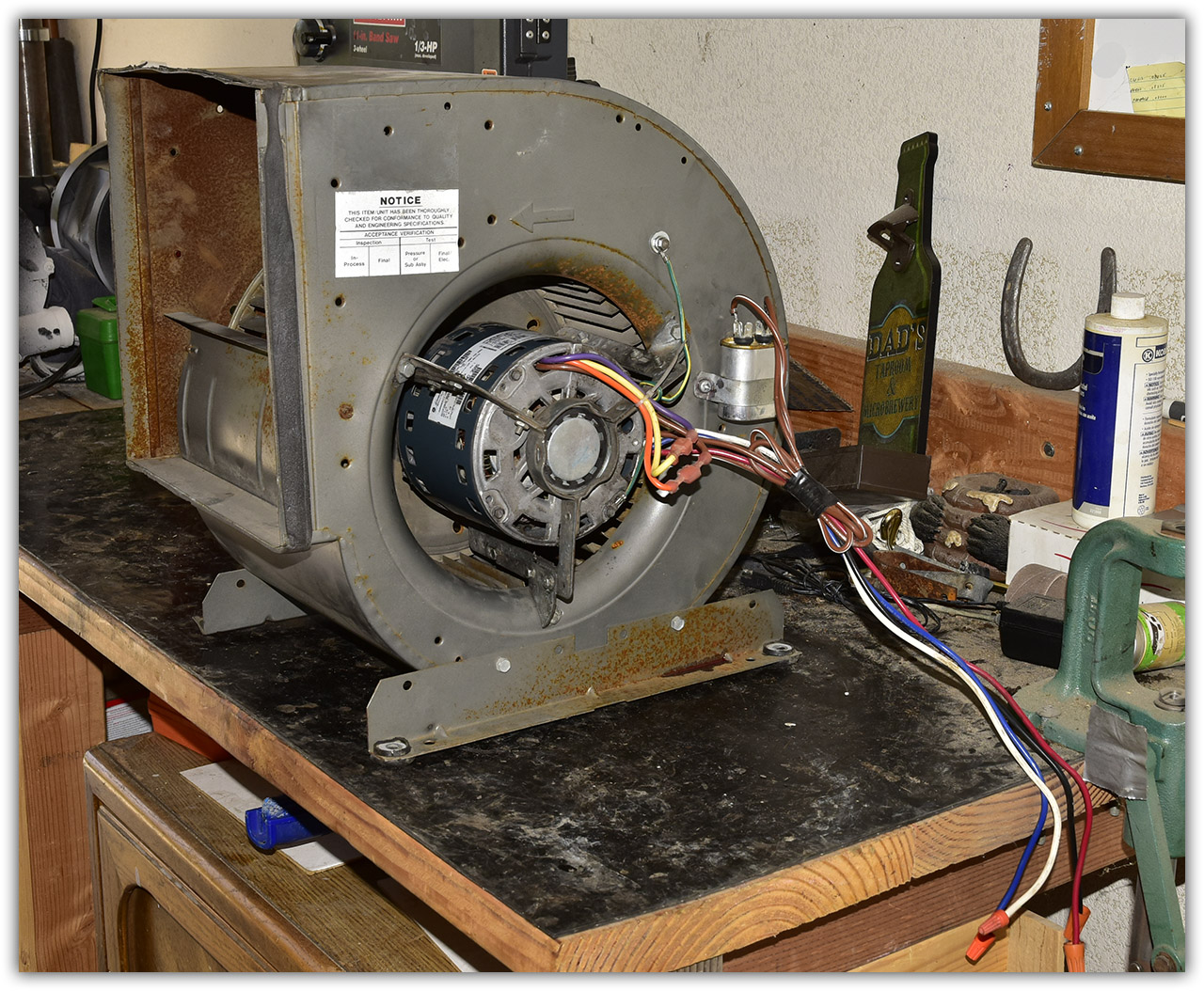

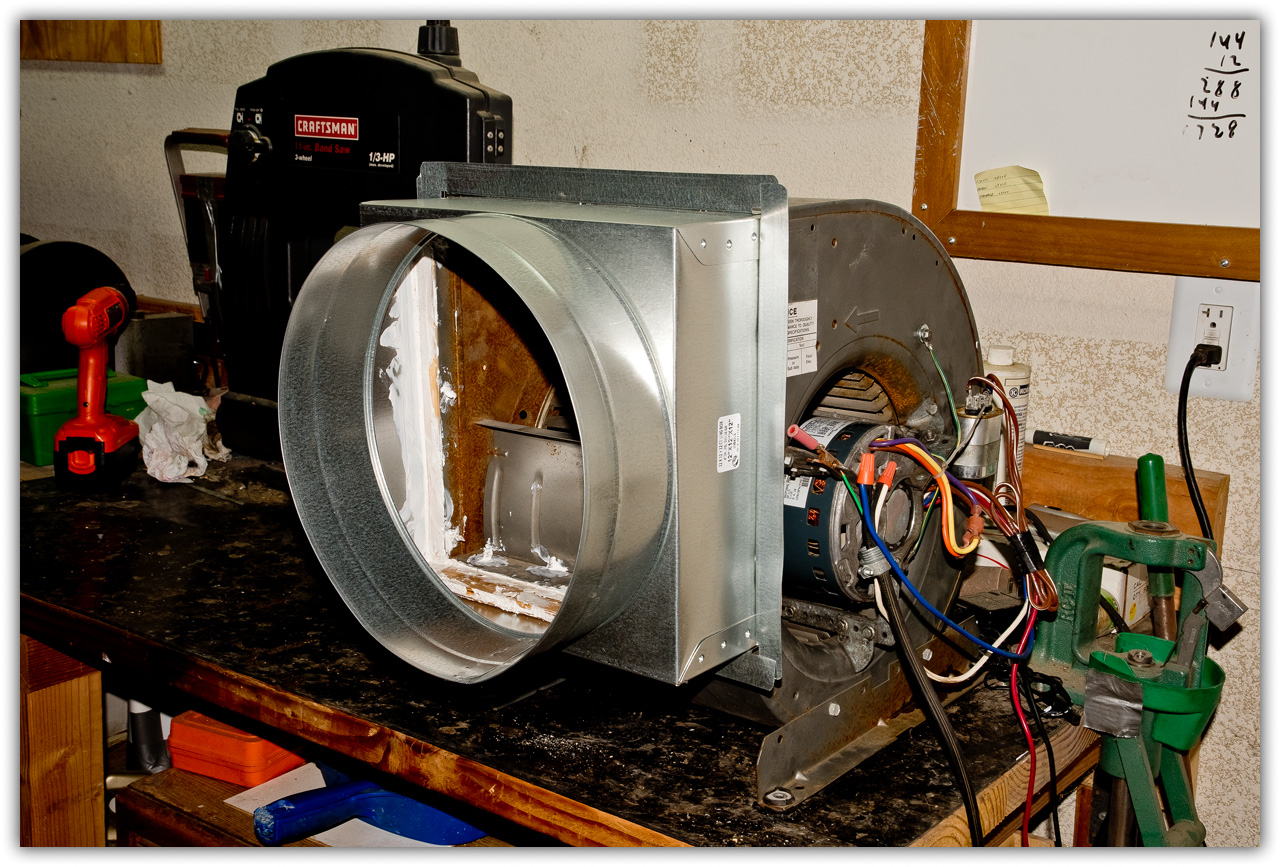

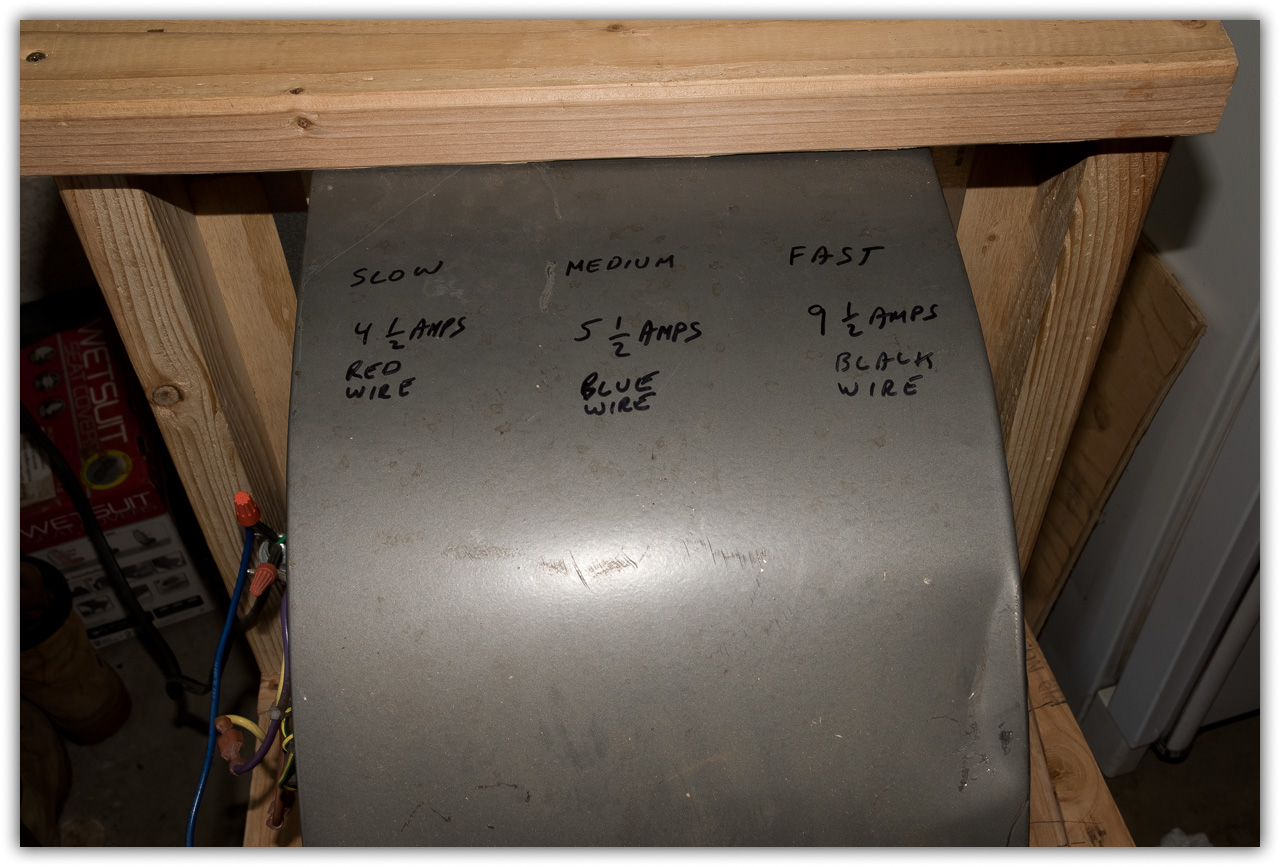

The concept of moving hot air from the living room has been in mind since the fireplace was installed. What kick-started the project was a trip to Skee's Recycling in Fresno. When the metal I delivered was in the bin and I was waiting my turn, I saw a bunch of swamp coolers stacked in their yard. I asked if I could buy one. The response was unexpected: "You brought us a lot of metal, you can leave with "this metal" and we're even. So in trade, I came home with a 3 speed swamp cooler fan. It runs, too! All three speeds.

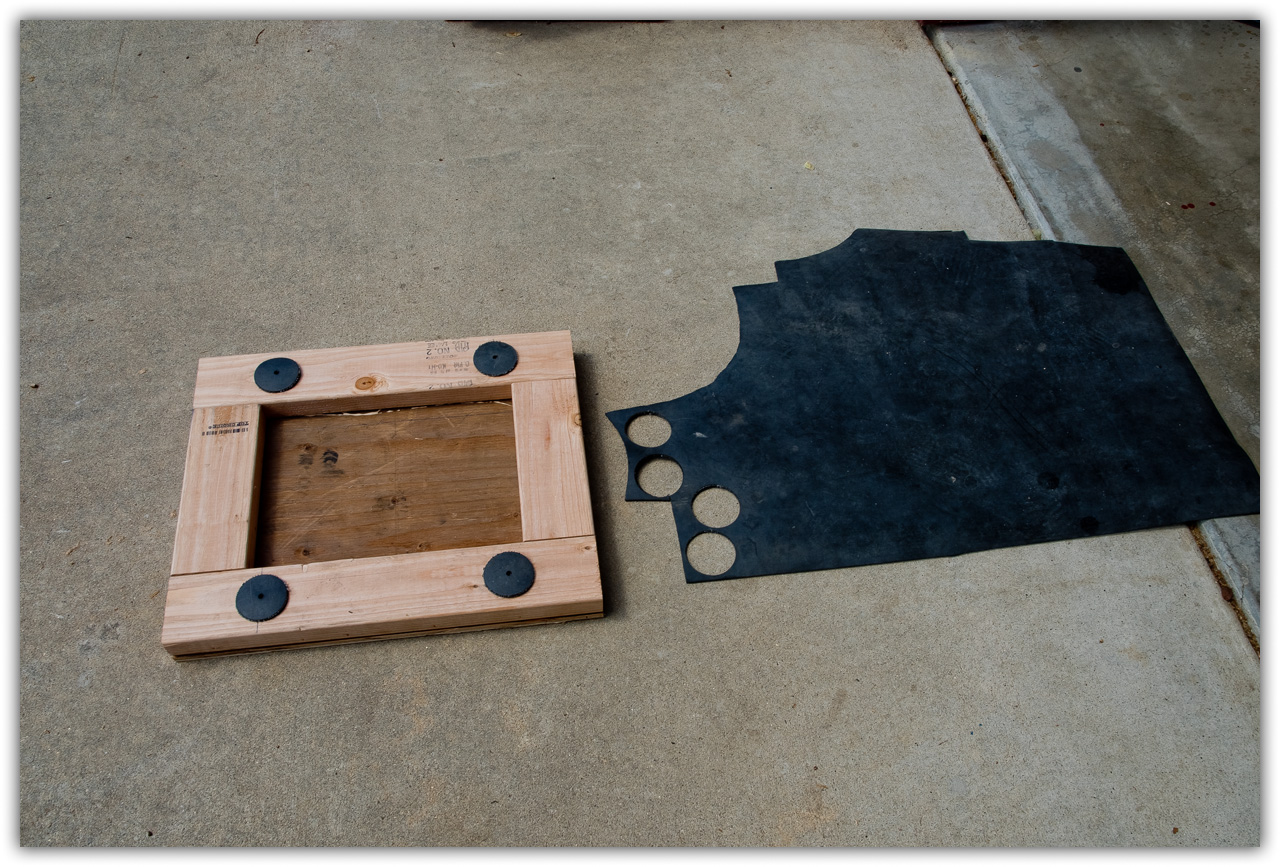

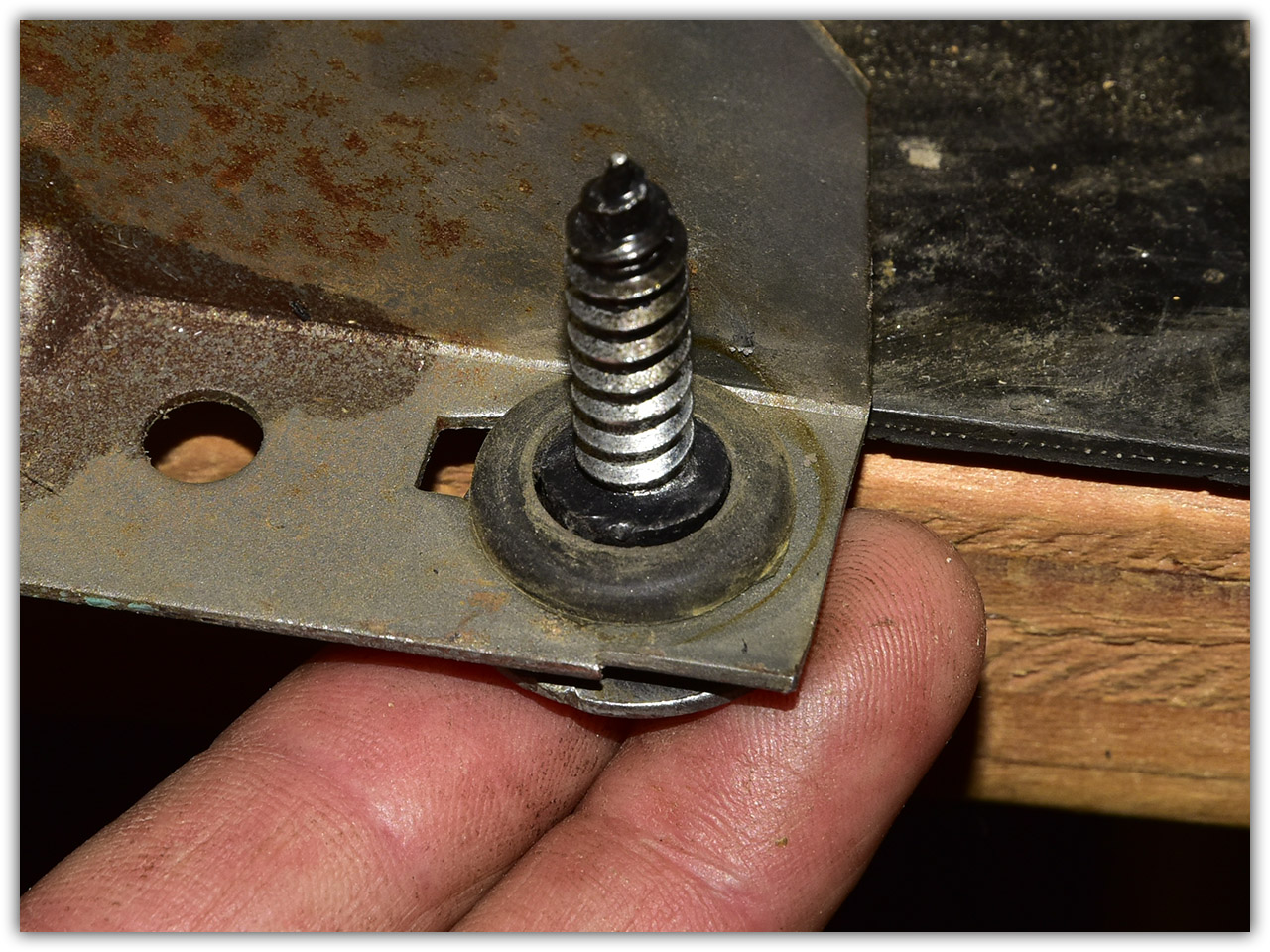

It was quite a project in itself to build a housing for it that will draw hot air from the ceiling area of the living room and blow it into the three bedrooms. That's the plan. This displays the build of the fan housing, prior to placement into the attic. |

Photo Details

This photo sequence contains 12 frames. Each frame is a finite 1280 pixels wide but height was left to its own based on the crop. I based the picture size on an email program's display window asuming that the picture would not be automatically resized to fit. This technique kept the file size down, the largest being just less than 658k making it easy to send and receive through email. All photos were taken with a Nikon D810.

Download Photo Project

|

|---|