|

Firewood Sheds

About the Photo Sequence

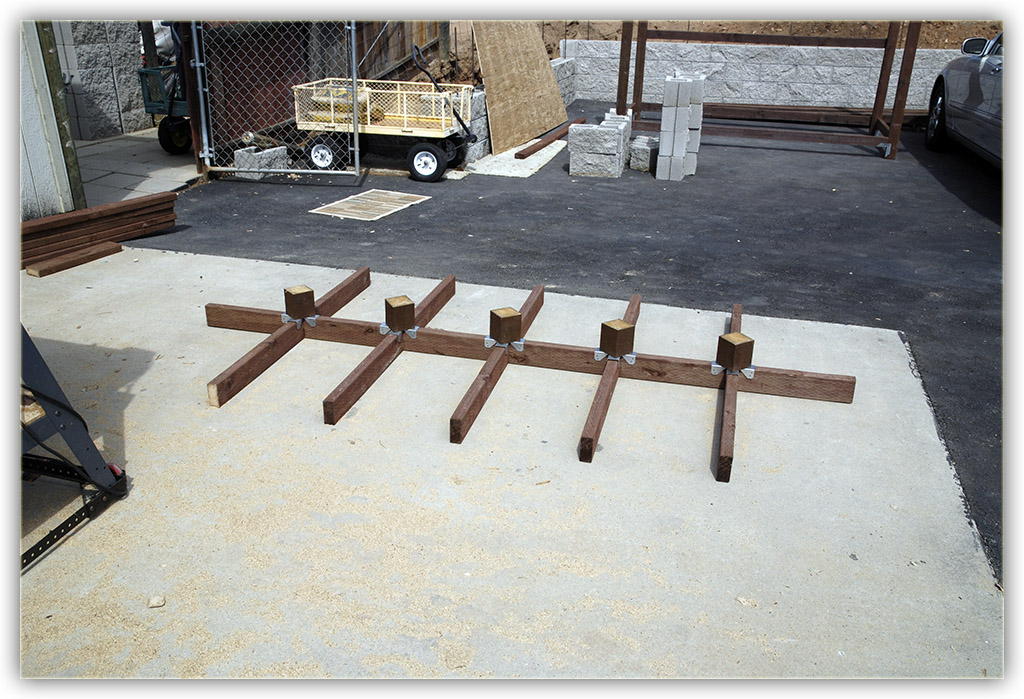

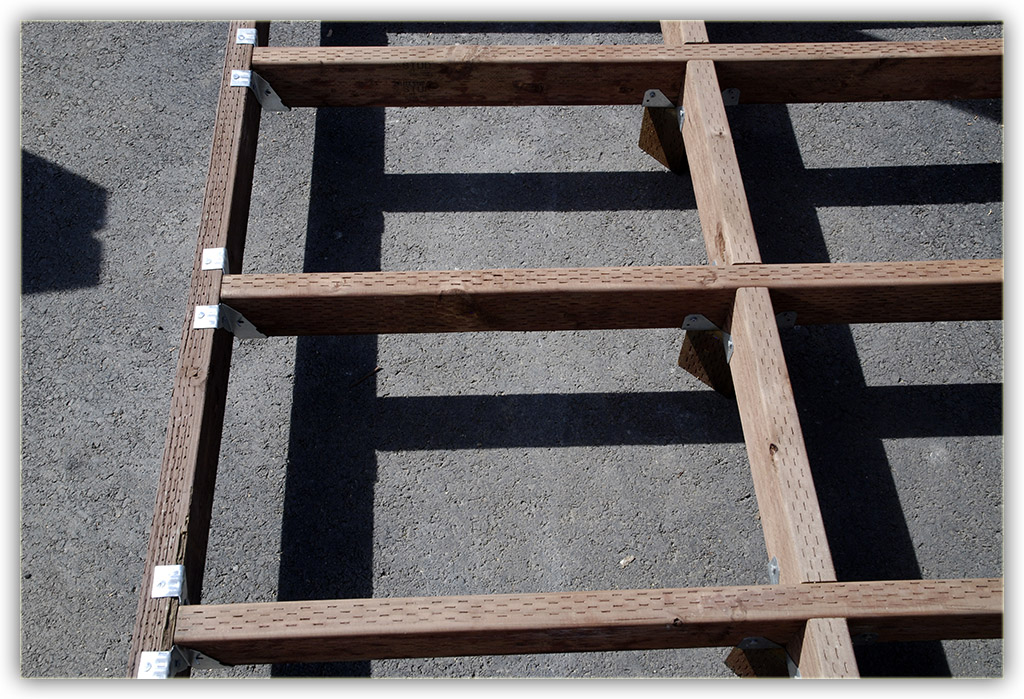

When the weather took down one of my oak trees, I was forced to chop it up for firewood. It became quite obvious I had no descent place to keep it. By descent, I mean off the ground and under a roof. I was forced to quickly build a couple of firewood sheds. My style is overkill. If its not fit for a castle, I don't want it. Besides, building these sheds is fun!

|

Photo Details

This photo sequence contains 16 frames. Each frame is a finite 1024 pixels wide but height was left to its own based on the crop. I based the picture size on an email program's display window asuming that the picture would not be automatically resized to fit. This technique kept the file size down, the largest being just less than 400k making it easy to send and receive through email. The file names are also numbered so they'll display in numerical order. All photos were taken with a Nikon D80.

Download Photo Project

|

|---|